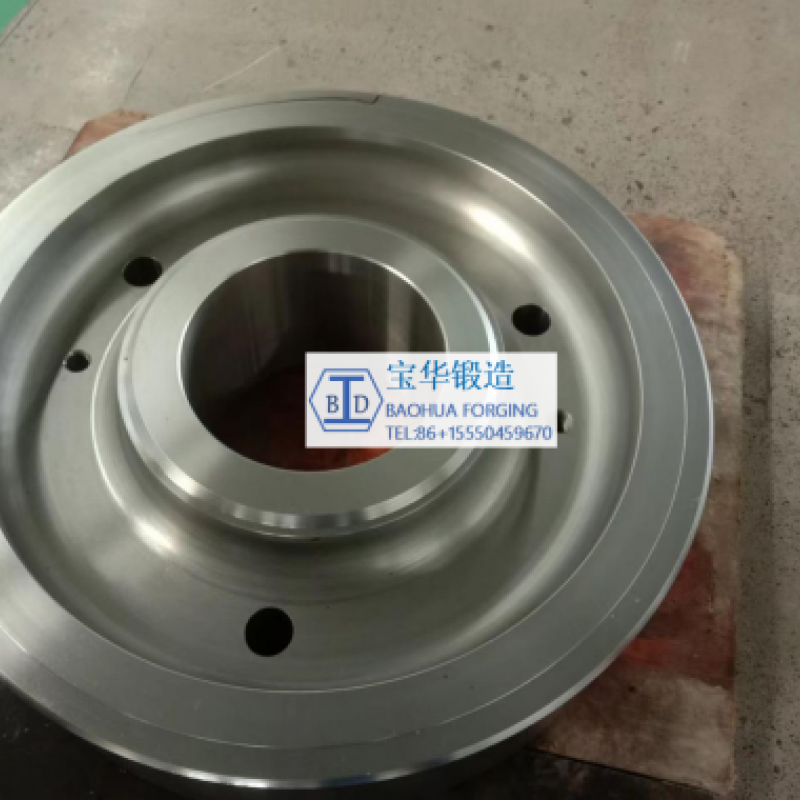

Gear is a commonly used mechanical transmission element, which is used to transmit torque and rotary motion. It is composed of one or more tooth top parts, with tooth grooves or teeth marks, and the transmission of force and motion between gears is realized by meshing. Attached product information:MATERIAL18CrNiM07-6HARDNESS140-240INNER DIAMETER210OUTSIDE DIAMETER610Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians.

Свяжитесь с нами

The internal gears produced by our Baohua Company are mainly used in the equipment accessories of petroleum industry and construction machinery. Forging the internal gear size according to the customer's requirement of using round steel in product materials.

Свяжитесь с нами

Gear is a common mechanical transmission device, which consists of one or more gears. Product details are as follows:NAMEGEARMATERIAL18CrNiMo 7-6HARDNESS140-240INNER DIAMETER121OUTSIDE DIAMETER299.48Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Свяжитесь с нами

Gear is a common mechanical transmission device, which consists of one or more gears. The finished gear is mainly made of 18CrNiMo7-6. After turning, milling, drilling, planing, rolling, shaving, grinding and heat treatment. Further finish machining from primary machining. Details of this product are as follows:Product NameGear FinishedMaterial18CrNiMo7-6HARDNESS140-240INNER DIAMETER210OUTSIDE DIAMETER611Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Свяжитесь с нами

Our baohua employer became founded in 1969. after three generations' hard paintings, it now covers an area of 50,000 ㎡ and has a constructing location of 25,000 ㎡. there are 260 personnel and 46 engineering technicians. the once a year output of forgings is 30,000 heaps. mainly in the car, hydraulic equipment, wind strength era, petroleum machinery parts, creation equipment, mining, metallurgy, shipbuilding machinery and other industries to supply related accessories. the goods bought are oriented at domestic and abroad.

Свяжитесь с нами

Brake housing products refer to mechanical parts that have the functions of slowing down, stopping or maintaining the stopped state of moving parts (or moving machinery).The brake housings produced by our Baohua company are mainly used in large-scale equipment with high safety requirements such as construction machinery.

Свяжитесь с нами

Our company independently designs dies and forges according to product specifications. Material types and weights can be made according to customer requirements. Our company also has rough machining, heat treatment and fine machining, which can be delivered according to the requirements of customers in different delivery states. About finish machining, we have more than 80 sets of different processing machinery and equipment, as well as ZEISS three-coordinate, Japanese small plate profilometer, gear tester, OmeGA tool counter and other inspection and testing equipment.

Свяжитесь с нами

For the forging and casting of screw tee, our Baohua Company mainly focuses on forging. Customers can make requests according to their own needs, and we will carry out forging production according to the drawings provided. Like simple and numerous products, our company's mold engineers improve the production speed and accuracy of products by building molds. For our enterprise itself, from the state-owned to the individual, it has gone through three generations of family management, and the equipment is constantly updated.

Свяжитесь с нами

Our agency independently designs dies and forges in step with product specs. material kinds and weights may be made consistent with patron necessities. our business enterprise additionally has rough machining, warmness treatment and satisfactory machining, which may be brought consistent with the requirements of customers in exceptional shipping states.

Свяжитесь с нами

According to your needness, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 6kg-500kg, Forging needs to be completed through heating, pre-forging, forming, trimming and other processes.According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.1. Free forging.

Свяжитесь с нами

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.The forging equipment of our Baohua company mainly includes: five tons and three tons of free forging hammers, 2500 tons, 1000 tons and 600 tons of friction presses, six large splint hammers and various types of air hammers, and 1000 tons of multi-directional die forging presses.

Свяжитесь с нами

Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing. And has ISO 9001, API 20b and API Q1 certificates.

Свяжитесь с нами

Our company has ISO9001, API, SQ and different certificate, more than 80 units of processing machinery and equipment, in addition to zeiss cmm, japanese small plate profiler, gear detector, ω mega tool placing device and other inspection and trying out system.For the production of Crusher Hammer, our organisation can independently design the mould consistent with the drawings furnished by means of the customer, and use one-of-a-kind materials consistent with the product specifications, through a sequence of techniques consisting of hard machining, heat remedy, and completing for mass productio

Свяжитесь с нами

Our company is able to design dies independently and forge according to product specifications. Material type and weight can be made according to customer requirements. Our company can design the die according to the drawings provided by customers, thus realizing the precision forging, which makes the material utilization more than 90%, thus greatly saving the cost.In addition, our company also has rough machining, heat treatment and finish machining, a complete line process, and delivery according to customer requirements of different delivery status.

Свяжитесь с нами

Our company is able to design the die according to the drawing according to the customer's requirements and achieve precision die forging, so that the utilization rate of rough rotor materials can reach more than 90%, which greatly saves costs. Our company can deliver according to the needs of customers with different delivery status. The quantity can also be purchased from one to more.Welcome customers to consult online.According to ISO standards, a rotating body supported by bearings is called a rotor.

Свяжитесь с нами

The internal gear ring is a kind of ring-shaped part with internal tooth structure, which is usually used in reducers and hydraulic machinery in mechanical transmission systems. The input speed and torque can be reduced and increased at the output end through the gear transmission of the internal gear ring.Baohua company was founded in 1969, from the initial initial processing to the industrial production of blank, quenching and tempering, rough machining, heat treatment, nitriding and finishing.

Свяжитесь с нами

Our company can independently design and process forging dies according to the drawings, and has many years of experience in forging planetary carriers. The weight of the forged planet carrier product can reach 6kg-400kg, and the forging needs to be completed through heating, pre-forging, forming, trimming and other processes.

Свяжитесь с нами

Output gear shaft, according to customer requirements can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials, according to the weight of different forging equipment units for forging, the weight of forged products can be To reach 6kg-500kg, forging needs to be completed through heating, pre-forging, forming, trimming and other processes.Customers in any industry using output gear shafts can request a quote for any quantity of forged gear shafts, from one prototype at a time and small batches to high volume production.

Свяжитесь с нами

Our manufactured output gear shaft can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials according to customer requirements. Forging can be carried out on different forging equipment units according to different weights. The forged product can weigh up to 6kg-500kg. The forging process needs to be completed by heating, pre-forging, forming and trimming. All these processes are integrated by our Baohua Company, thus ensuring the quality of products.In the design, the application of gear shaft generally involves the following situations:1.

Свяжитесь с нами

Gear is a commonly used mechanical transmission element, which is used to transmit torque and rotary motion. It consists of one or more tooth tips, usually in the shape of a disk or a cylinder. The main function of gear is to realize the transmission of speed and torque, and at the same time, it can also change the steering and transmission direction.NAMEGEARMATERIAL18CrNiM07-6HARDNESS140-240INNER DIAMETER121OUTSIDE DIAMETER299.48Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Свяжитесь с нами

The internal gear ring is a kind of circular gear, the teeth of which are inward. It is usually used to transmit mechanical systems such as differential, reducer, steering gear, planetary gear box, etc.

Свяжитесь с нами

Our company independently designs dies and forges according to product specifications. Material types and weights can be made according to customer requirements. This gear company independently designed the die to achieve precision forging, so that the material utilization rate reaches more than 90%, which greatly saves the cost. Our company also has roughing, heat treatment and finishing, which can be delivered according to customer requirements in different delivery states.

Свяжитесь с нами

The output tools shaft synthetic by means of us can be product of forty five#, 40cr, 30crmo, 35crmo, 42crmo, 18crnimo7-6 and other substances according to consumer requirements. it can be forged on different forging device gadgets in step with one-of-a-kind weights. the forging product weight can attain 6kg-500kg. the forging method wishes to be finished by means of heating, pre-forging, forming and trimming.According to the different shapes of axes, shafts can be divided into crankshaft and straight shaft.

Свяжитесь с нами

According to customer requirements, 4140, 4130, 45 #, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials can be made. Forging can be carried out on different forging equipment units according to different weights. The weight of forged products can reach 6kg-2000kg. Forging needs to be completed through heating, pre forging, forming, trimming and other processes to increase the forging ratio and stability of products. Flange forgings can be finished to meet the final assembly conditions.Threaded flange refers to a kind of flange which is connected with pipe by thread.

Свяжитесь с нами