The manufacturing of connector is particularly used within the accessories of oilfield wellhead system. we are able to layout dies in keeping with the drawings furnished by means of you and carry out mass die forging, as a result decreasing the price.The connectors produced by using our employer are specifically used within the petroleum industry. uncooked substances are purchased from round steel with recognized excellent at home and abroad.

Свяжитесь с нами

The production of connector is mainly used in the accessories of oilfield wellhead equipment. We can design dies according to the drawings provided by you and carry out mass die forging, thus reducing the cost.The connectors produced by our company are mainly used in the petroleum industry. Raw materials are purchased from round steel with recognized quality at home and abroad. We can forge the corresponding model of dies and hammers according to customers' requirements, thus improving production efficiency and saving time.

Свяжитесь с нами

Connectors refer to components used to connect electrical components or electronic devices, which are an indispensable part of electronic circuits.Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Свяжитесь с нами

Connectors refer to components used to connect electrical components or electronic devices, which are an indispensable part of electronic circuits. The connector can be connected with power supply, signal and control lines to make the circuit work normally and reliably.The features of the connector are as follows:1. High reliability: the connector is made of finished materials, which has good mechanical properties and corrosion resistance and can work stably for a long time.2.

Свяжитесь с нами

Casing head is generally cast from steel and usually includes two main parts: outer jacket and inner lining. The outer jacket is the outermost layer inserted into the next casing, and the inner liner is the inner layer inserted into the next casing. The casing head also includes some other connecting parts, such as threaded rings and sealing rings.The connectors produced by our company are mainly used in the petroleum industry. Raw materials are purchased from round steel with recognized quality at home and abroad.

Свяжитесь с нами

Gear is a common mechanical transmission device, which consists of one or more gears. Product details are as follows:NAMEGEARMATERIAL18CrNiMo 7-6HARDNESS140-240INNER DIAMETER121OUTSIDE DIAMETER299.48Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡. There are 260 employees and 46 engineering technicians. The annual output of forgings is 30,000 tons.

Свяжитесь с нами

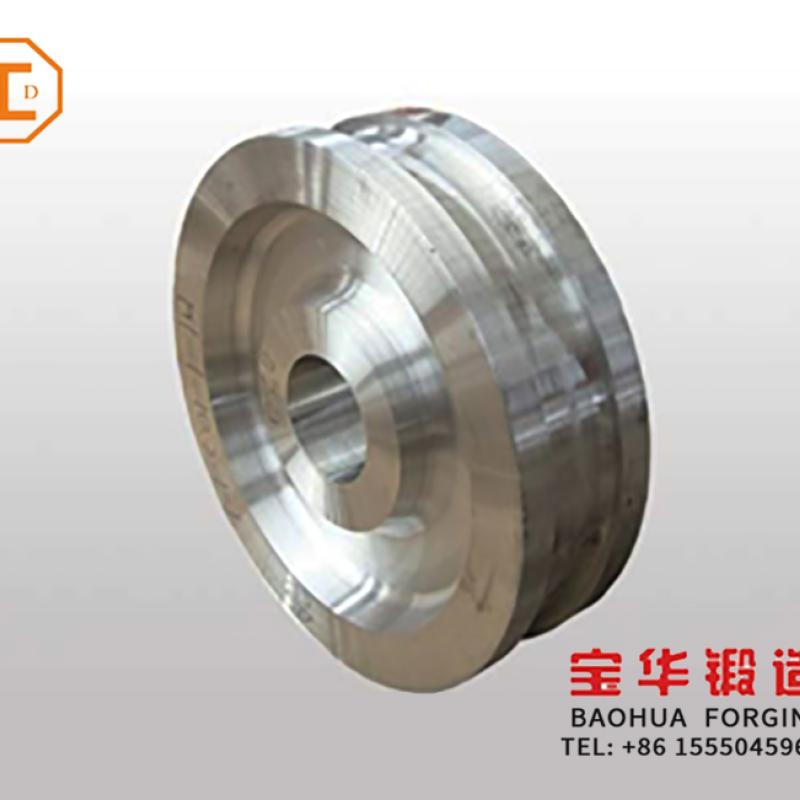

The internal gear ring produced by our Baohua Company is mainly used in the oil industry and equipment accessories of construction machinery. Forging the size of the internal gear ring according to the requirements of customers for using round steel in product materials.

Свяжитесь с нами

BAOHUA produces forged gear, ring gear shapes for single, double and other near net shapes for finishing into several different shapes. OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsThese forged gear shapes can be made from ferrous and non-ferrous metals including carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and tool steel.Forging gear and ring gear blank processBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower volume requir

Свяжитесь с нами

The booster ring, also known as the booster ring, is an annular seal used to seal and protect equipment in high pressure environment. It is usually made of highly elastic materials, such as fluororubber or silicone rubber, to ensure stable sealing performance.

Свяжитесь с нами

The internal tools ring produced by using our baohua organization is specifically used within the oil enterprise and gadget accessories of creation equipment. forging the scale of the internal gear ring according to the necessities of clients for the use of spherical metal in product materials.

Свяжитесь с нами

Forging gear and ring gear blank processBAOHUA makes use of a unbroken rolled ring method to offer cast tools producers with shape, length and material flexibility, decrease volume necessities and near-completed shapes to store on very last machining costs. Higher nice and accelerated electricity and put on in cast tools blanks is done from contoured grain flow, decreased grain length and thermal processing that improves mechanical residences and metallurgical soundness from the open die forging manner.

Свяжитесь с нами

The higher quality and higher strength and wear of this product's forged gear bracelet is achieved through shaped grain flow, reduced grain size and thermal processing. Thereby, the mechanical properties and metallurgical stability of the open-die forging process are improved. All of our forgings can go through hot die forging, roughing, heat treatment, etc.

Свяжитесь с нами

BAOHUA produces solid gear, ring gear shapes for single, double and different close to internet shapes for completing into numerous unique shapes.OUR FORGED GEAR SHAPES & ALLOYSHelical GearsBevel GearsHypoid GearsWorm GearsSpiroid GearsTorsoing GearsThese forged gear shapes may be crafted from ferrous and non-ferrous metals which include carbon steel, alloy steel, stainless steel, titanium, nickel, aluminum and device steel.Forging gear and ring gear blank processBAOHUA uses a seamless rolled ring process to provide forged gear manufacturers with shape, size and material flexibility, lower

Свяжитесь с нами

The internal gear ring is a kind of circular gear, the teeth of which are inward. It is usually used to transmit mechanical systems such as differential, reducer, steering gear, planetary gear box, etc.

Свяжитесь с нами

With regard to inner ring end cap, we can make many kinds of materials according to customer requirements, such as 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6, etc. Our company independently develops ring forging process, which can greatly improve forging efficiency and reduce blanking weight, and ultimately achieve the purpose of cost saving. According to the weight, forging is carried out on different forging equipment units. The weight of forged products can reach 6kg-2000kg. The forging process needs to be completed by heating, pre-forging and forming.

Свяжитесь с нами

Our corporation makes use of the seamless rolling ring process, which makes the product more solid and can greatly reduce the weight of blanking and save fee.

Свяжитесь с нами

The internal gears produced by our Baohua Company are mainly used in the equipment accessories of petroleum industry and construction machinery. Forging the internal gear size according to the customer's requirement of using round steel in product materials.

Свяжитесь с нами

The purpose of the utility model is to overcome the above shortcomings of the prior art, propose a tooling for gear end caps, which can realize the positioning and fixation of various types of gear end caps.In order to achieve the above purposes, the utility model adopts the following technical solutions:The utility model relates to a tool for a gear end cover, which comprises a support plate for supporting the gear end cover; The gear end cover comprises a circular main body, a plurality of positioning holes on the main body, and a plurality of bolt holes on the main body; The positioning hol

Свяжитесь с нами

Baohua company was established in 1969, from the initial rough machining to further finishing production. From three sets of processing equipment to more than 80 sets of processing equipment and inspection equipment, all of them are based on the production concept of honesty and customer-oriented.In general, the materials used in the production of gear rings are made of 45 or 40Cr steel.

Свяжитесь с нами

The inner gear ring produced by way of our baohua company is in particular used within the oil enterprise and gadget add-ons of construction equipment. forging the dimensions of the internal equipment ring in line with the requirements of clients for using spherical metallic in product materials. batch purchase can open molds for specialised deliver and finishing production. At present, our organization has more than one hundred cnc lathes and finishing system.

Свяжитесь с нами

The internal gear ring produced by our Baohua Company is mainly used in the equipment accessories of petroleum industry and construction machinery. Forging the size of the internal gear ring according to the requirements of customers for using round steel in product materials. Batch purchase can open molds for specialized supply and finishing production.Flanges can be made of a variety of materials including but not limited to 4140, 4130, 35CrMo, 20CrMnMO, and can be forged and machined with a diameter of 200mm to 3000mm.

Свяжитесь с нами

Gear is a common mechanical transmission device, which consists of one or more gears. The finished gear is mainly made of 18CrNiMo7-6. After turning, milling, drilling, planing, rolling, shaving, grinding and heat treatment. Further finish machining from primary machining. Details of this product are as follows:Product NameGear FinishedMaterial18CrNiMo7-6HARDNESS140-240INNER DIAMETER210OUTSIDE DIAMETER611Our Baohua Company was founded in 1969. After three generations' hard work, it now covers an area of 50,000 ㎡ and has a building area of 25,000 ㎡.

Свяжитесь с нами

The joint joints produced by our Baohua company are mainly used in the wind power industry and equipment accessories of construction machinery. Forging the size of the internal gear ring according to the requirements of customers for using round steel in product materials. Bulk purchasing can open molds for specialized supply and finishing production.

Свяжитесь с нами

According to customer requirements, it can be made of 45#, 40Cr, 30CrMo, 35CrMo, 42CrMo, 18CrNiMo7-6 and other materials. According to different weights, it can be forged on different forging equipment units. The weight of forged products can reach 60kg-7000kg, Forging needs to be completed through heating, pre-forging, forming and other processes.The die movement and degree of freedom of the forging equipment are inconsistent. According to the deformation limitation characteristics of the lower dead center, the forging equipment can be divided into the following four forms:1.

Свяжитесь с нами